FOOD & BEVERAGE

Experience a cleaner clean

with a fraction of the waste

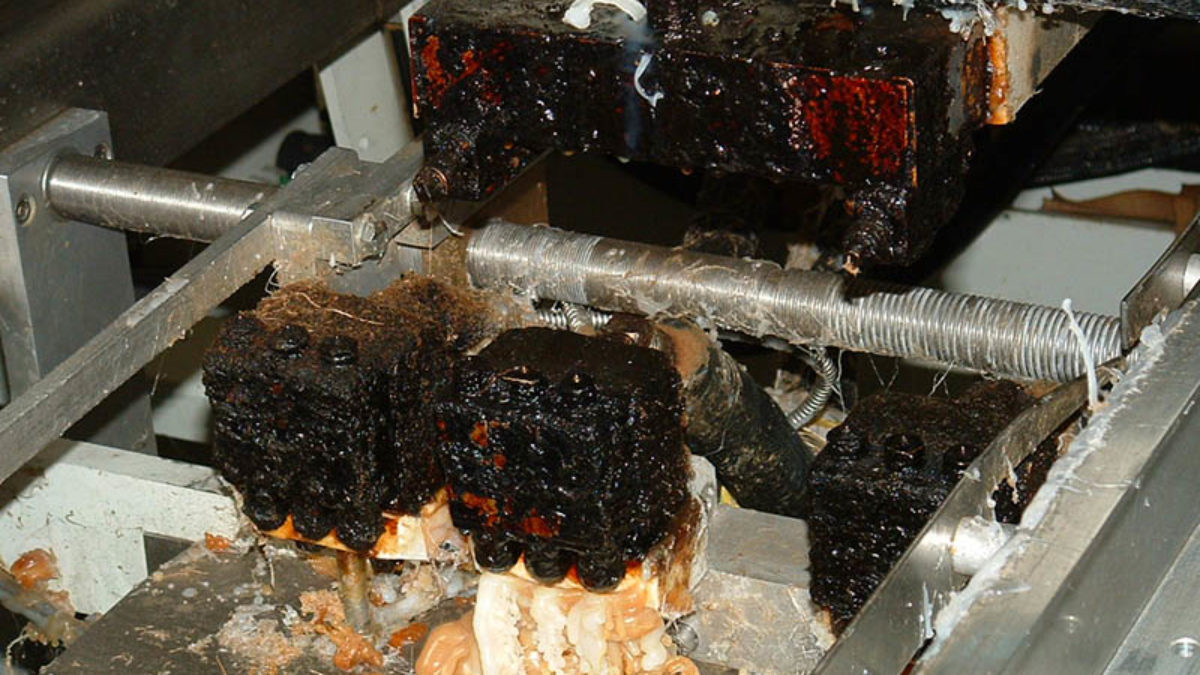

Food processing and packaging equipment accumulates grease, carbonised

residue, seasonings, proteins, harmful bacteria, biofilms, adhesives, labels

and many other contaminants that traditionally take significant time to clean.

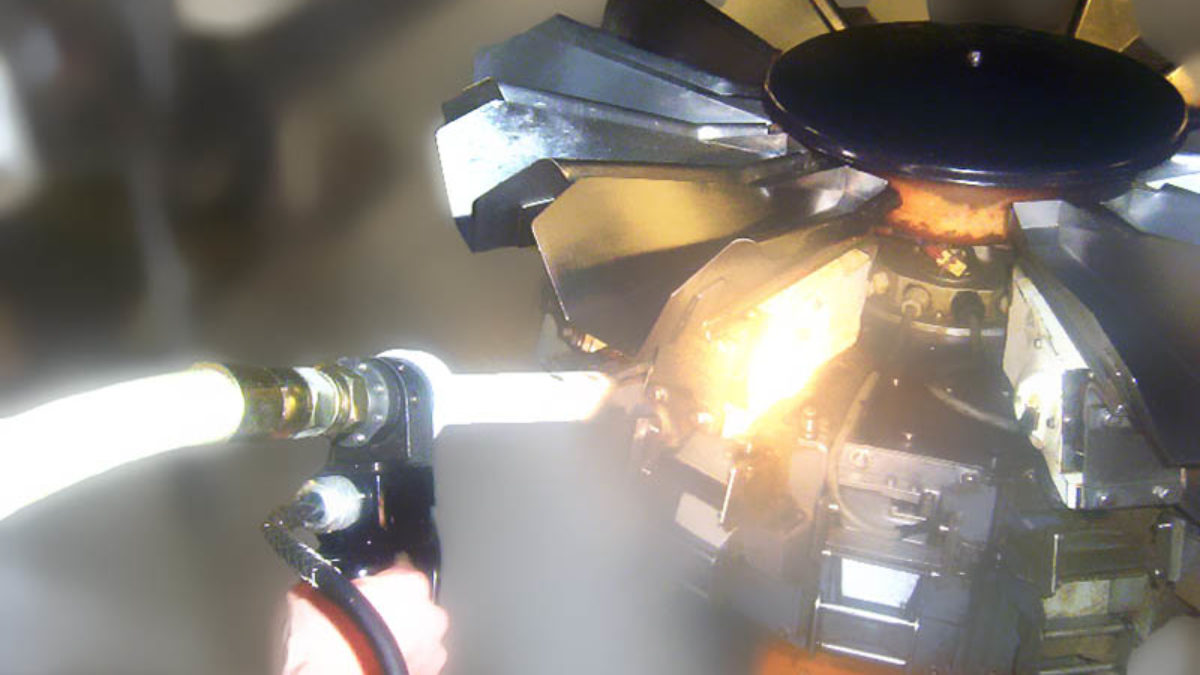

Dry ice cleaning provides an in-situ cleaning solution that is non-destructive,

sustainable, does not use water or chemicals and does not produce secondary waste.

CASE STUDIES

Revolutionize processes

to drive real results.

Processing & Packaging Equipment Cleaning

Increase line productivity by

getting a cleaner clean in less time

BENEFITS

Dry ice blasting thoroughly cleans contamination from process and production equipment in-place, without water or chemicals, and even while the equipment is still running.

- Reduce cleaning time and resulting downtime

- Clean hot and online

- No secondary waste

- Non-Abrasive

- Will not damage equipment

- Get a cleaner clean

- Reduce bacteria counts and remove biofilms

- Reduce risk of unplanned production stoppages and costly repairs

SPECIFIC USE CASES:

- Mixers and blenders

- Slicers and dividers

- Roasters, ovens and proofers

- Dryers, extruders and molds

- Conveyors and chains

- Radial feeders (Ishida Weighers)

- Wrappers and packagers

- Baggers and pack-off tables

- Labelers, box formers and glue applicators

- Mills and load-out bins

- Palletizers and de-nesters

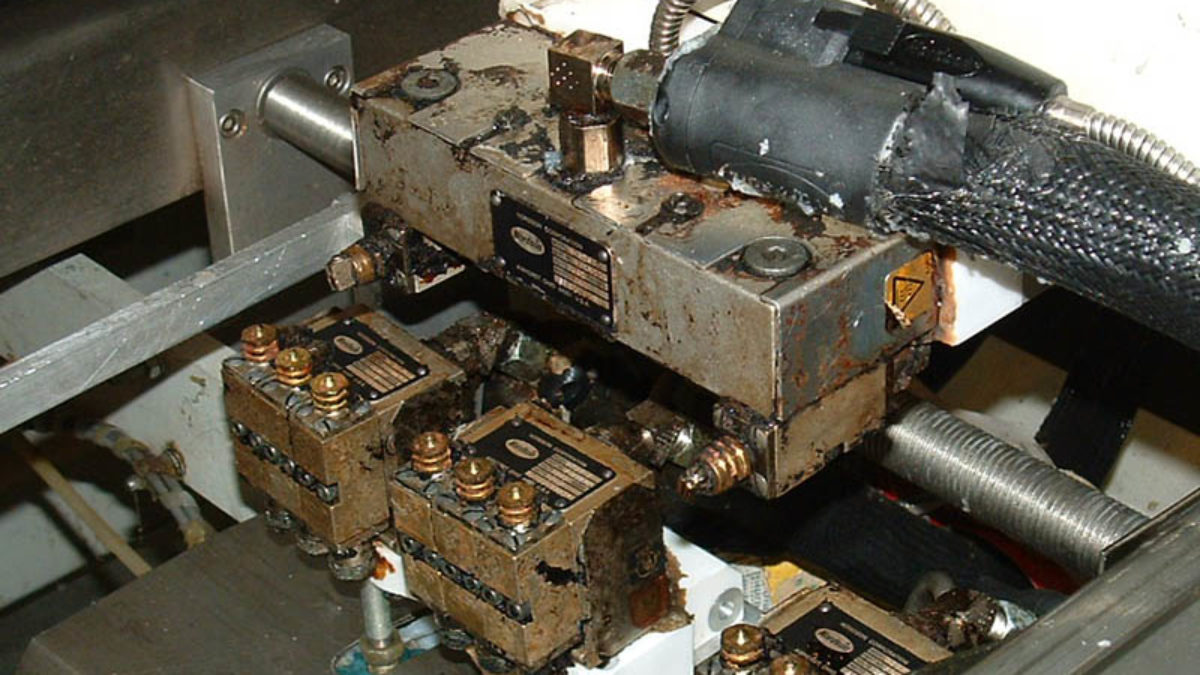

- Electrical components and motors

- Cold storage

BENEFITS OF DRY ICE BLASTING

Dry ice blasting is a dry cleaning

process that does not produce

secondary waste or residue

Dry ice cleaning offers an effective, dry, sustainable and non-destructive cleaning method that can be performed in-place, which eliminates or reduces costly shutdown time for cleaning. Hard to reach corners and crevices are easily cleaned with dry ice blasting, resulting in an improved overall clean in your plant.

Not only does dry ice cleaning remove contaminants, but it will also result in log reductions in bacteria counts and will remove biofilms without water or chemicals* – all while significantly reducing cleaning time, labor and overall costs.

→ Clean online or in place, even while equipment is hot and running

→ Eliminate or drastically reduce disassembly

→ No water, chemicals or secondary waste streams

→ No masking or drying time

→ Non-conductive

Clean electronics, sensors and motors without damage

→ Reduce cleaning time and labor costs

→ Remove biofilms without water or chemicals

→ Lower bacteria counts (significant log reductions)*

→ Environmentally responsible