DRY ICE BLASTING APPLICATIONS:

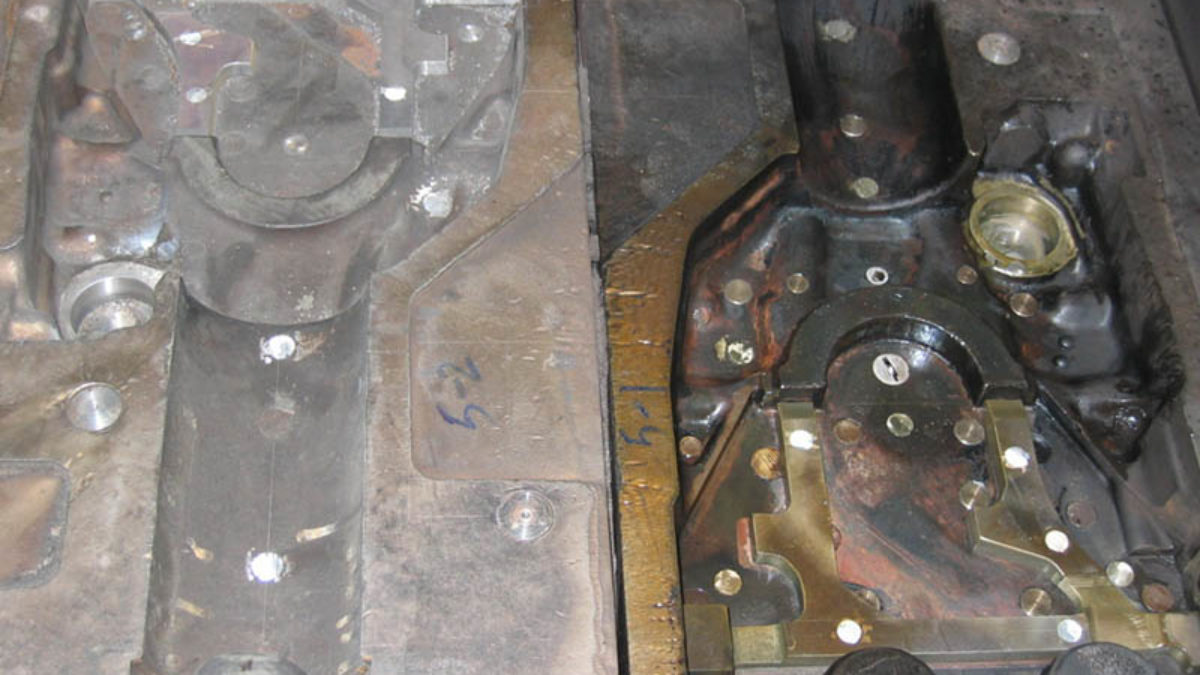

Core Box Cleaning

Safely clean core boxes online, while reducing downtime, improving product quality and eliminating the risk of damage

Buildup of resin and sand on core box vents prevents core material from solidifying, and often causes vent clogging, which reduces product quality and creates scrap. Traditional cleaning methods are very slow, ineffective, can damage tooling and destroy vents on the core boxes.

Dry ice blasting quickly and safely removes the buildup while the core boxes are online without creating secondary waste. The process is non-abrasive and will not damage screens, vents or the tooling. Cleaning core boxes with dry ice cleaning leads to a significant reduction in production downtime and scrap rates.

SPECIFIC USE CASES

Dry ice blasting safely and effectively cleans all types of core boxes

RELATED INDUSTRIES

- Cold boxes

- Half core boxes

- Dump core boxes

- Split core boxes

- Strickle core boxes

- Left and right-hand core boxes

- Loose piece core boxes

- Gang core boxes

BENEFITS OF DRY ICE BLASTING

Regularly and reliably remove buildup from core boxes

Dry ice cleaning is non-abrasive and does not create secondary waste, which allows foundries to clean core boxes online at operating temperature.

→ Increase productivity and reduce downtime

→ Clean in-place

No cooldown or disassembly required

→ Non-abrasive

Safely clean without damaging vents or screens

→ Decrease cleaning time and labor costs

→ No secondary waste stream for disposal

→ Improve part quality and reduce scrap

→ Deliver superior as-cast finish

→ Employee safe

Reduce harmful chemicals and tedious manual cleaning

→ Environmentally responsible