ENGINEERED WOOD

A safer cleaning process that requires less

labor and eliminates manual cleaning

Dry ice blasting eliminates the manual cleaning of engineered wood presses, dryers

and vents, while eliminating employee exposure to unsafe conditions. The process

reduces overall cleaning time and provides a more effective cleaning result.

Revolutionize processes

to drive real results.

General Equipment Cleaning

Reduce cleaning time and production

downtime while prolonging life of equipment

BENEFITS

Dry ice cleaning quickly and effectively cleans composite wood production equipment without water, chemicals or secondary waste.

- No secondary waste

- Reduced fire hazard

- Clean in-place

no cool down required - Reduce labour costs

- Non-abrasive

Eliminate wear and tear on machinery - Reduce downtime

- Increase employee safety

Eliminate manual cleaning with chemical solvents - Reduce risk of unplanned production stoppages and costly repairs

- Environmentally responsible

SPECIFIC USE CASES:

- OSB presses

- Dryers

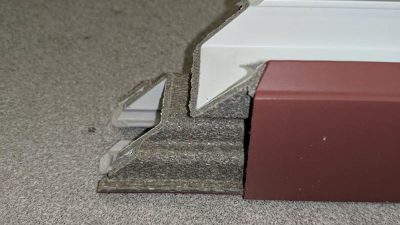

- Finger joint blade holders

- Glue applicators

- Peelers

- Lathes

- Pitch and resin removal

- Sanding belts

- Ventilation blades

- Wet scrubbers

- and more

BENEFITS OF DRY ICE BLASTING

Dry ice cleaning is a safer and more effective cleaning solution for composite wood presses and ancillary equipment

The typical cleaning process for tooling for engineered wood is time consuming, labor intensive and requires employees to work within close proximity to machines, hot residue and dust. Dry ice blasting provides a no-contact cleaning solution that is faster, safer and more effective.

→ Decrease cleaning time and labor costs

→ Non-abrasive

No damage to substrates

→ Clean in-place

No disassembly required

→ Increase productivity and reduce downtime

→ Non-conductive cleaning process

→ Employee safe

Reduce harmful chemicals and tedious manual cleaning

→ Environmentally responsible

→ Improve part quality and reduce scrap

→ No secondary waste stream