AUTOMOTIVE

Meet stringent industry demands

while increasing production uptime

Dry ice cleaning helps automotive facilities solve

a variety of cleaning challenges, allowing them

to increase productivity and improve part quality.

CASE STUDIES

Revolutionize processes

to drive real results.

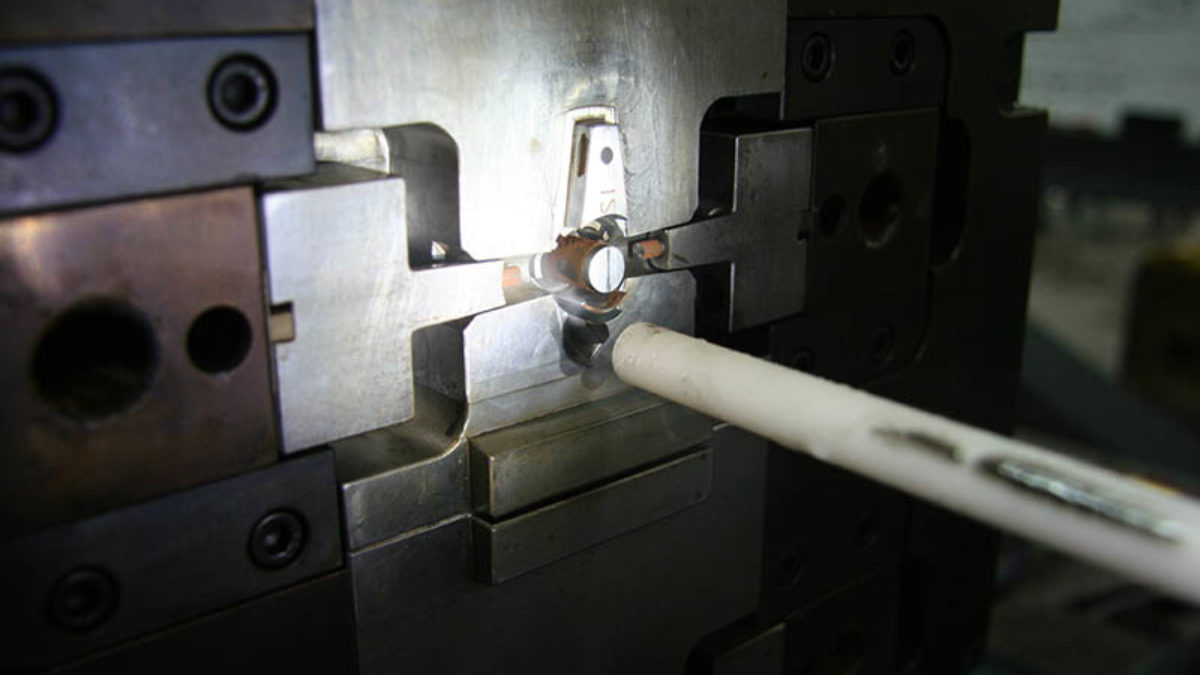

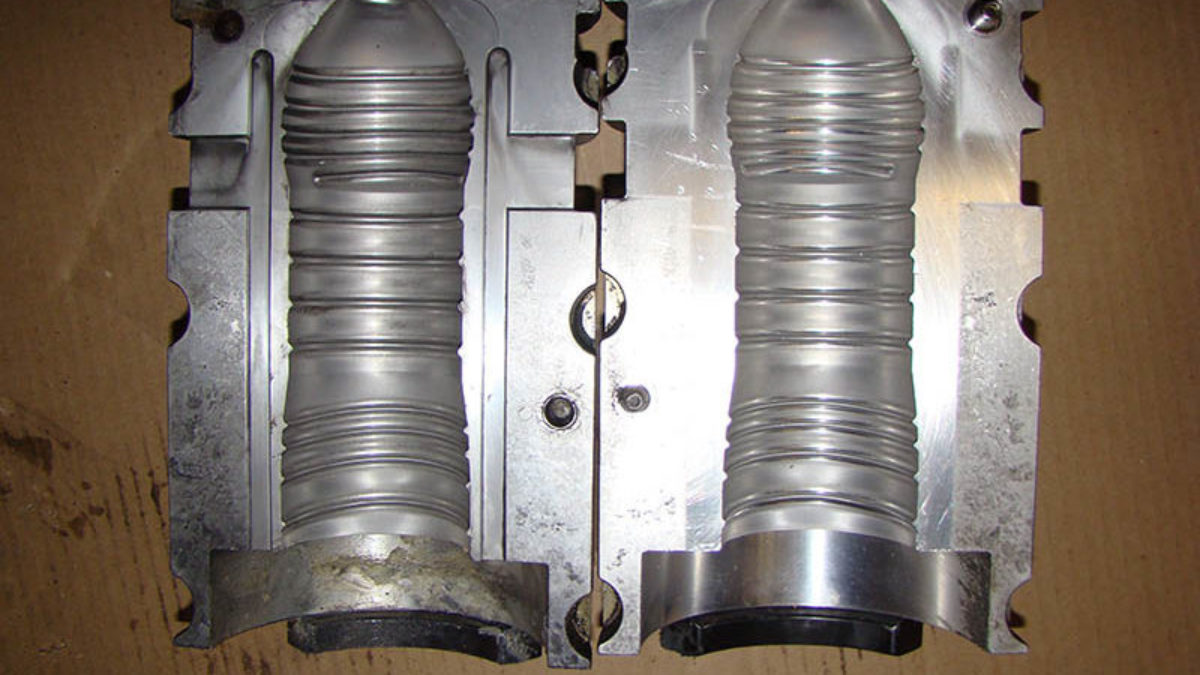

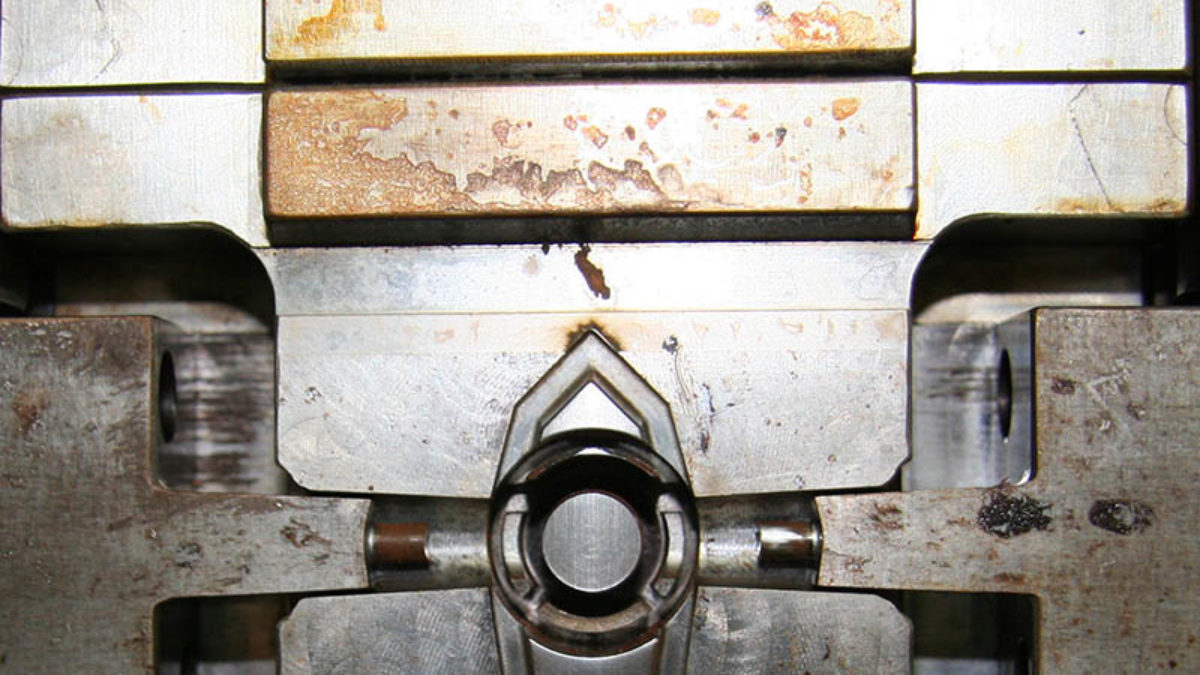

Mould Cleaning

Improve productivity by reducing downtime

BENEFITS

Dry ice cleaning is a non-abrasive method that safely cleans moulds online, at operating temperatures.

- Improve product quality

- Clean in-place

Little to no disassembly required - Non-abrasive

No damage to molds - Reduce scrap

Cleaner molds lead to higher quality - Meet stringent industry demands

6-Sigma, Kaizen, 5S, TPM (Total Productive Maintenance) - Reduce production downtime

Clean quicker and without cooldown or disassembly - Decrease cleaning time and labor costs

- Eliminate painstaking manual cleaning

SPECIFIC USE CASES:

- Injection molds

- Blow molds

- Compression molds

- Urethane molds

- Textured molds

- Slush molds

- Technical molds

- Extrusion dies

- Rotational molds

- LSR and LIM molds

- Thermoform molds

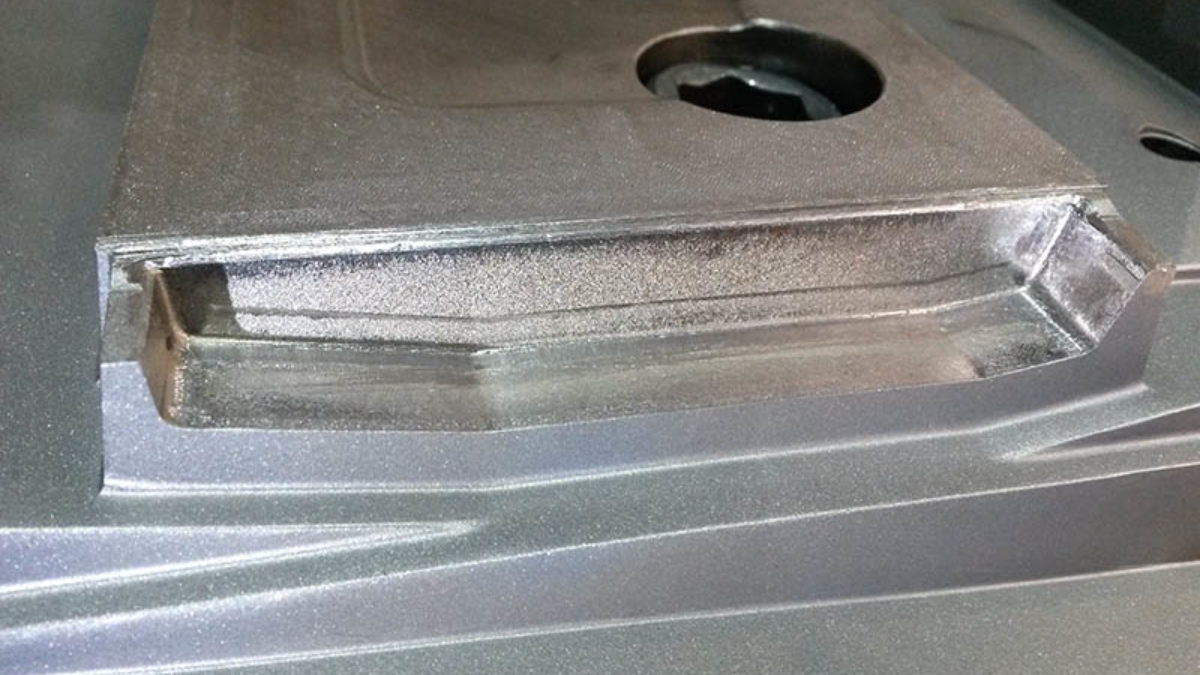

Surface Preparation

Prepare surfaces with a dry process that allows

for immediate coatings/paint application

BENEFITS

Dry ice cleaning is a dry process that eliminates the need for aqueous or chemical solutions on paint lines.

- Dry process allows for immediate paint or coating after cleaning

- No secondary waste

Reduce disposal costs - Non-abrasive

Will not damage parts - Improve product quality

- Environmentally responsible

SPECIFIC USE CASES:

- Interior parts

- Exterior parts

- Cleaning surfaces before RTVs

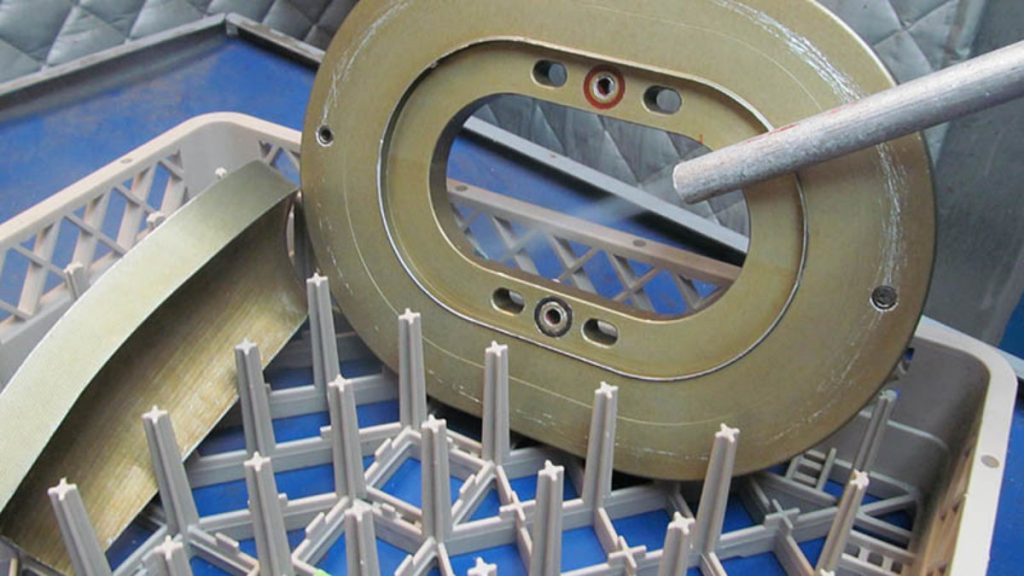

Paint and Coating Booth Cleaning

Reduce production downtime and scrap rates

BENEFITS

Dry ice blasting provides a quicker and more effective cleaning process and reduces the risk of unplanned production downtime.

- Reduce downtime associated with cleaning

- Reduce waste disposal costs

Eliminate water and secondary waste - Clean more effectively

- Increase production efficiencies

- Maximize equipment life

- Environmentally responsible

SPECIFIC USE CASES:

- E-coat and powder coat lines

- Paint hooks

- Spray booths

- Paint shop rollers

- Guide rails

- Reduction gearboxes

- Perforated shielding

- Flooring

Composite Tool Cleaning

Meet stringent industry demands while

protecting delicate tool surfaces and finishes

BENEFITS

Dry ice blasting quickly cleans a variety of tooling made of a varying degree of materials.

- Reduce production downtime

- Maximize tooling life

- Environmentally responsible

No secondary waste - Reduce cleaning time and labor costs

- Non abrasive

No damage to tooling surfaces - Clean a variety of materials with a single machine

- Clean tooling in place

- Eliminate chemicals and solvents

SPECIFIC USE CASES:

- Compression molding

- Resin transfer molding

- Extrusion

- Pre-pregging

- Wet-layup

- Teflon-coated tools

- Highly-polished tools

- Post-processing equipment

- Autoclave flooring walls

- PEEL, Kevlar, E-Glass, S-Glass, Spectra, Boron, Pultrusion, etc.

- LIM molding

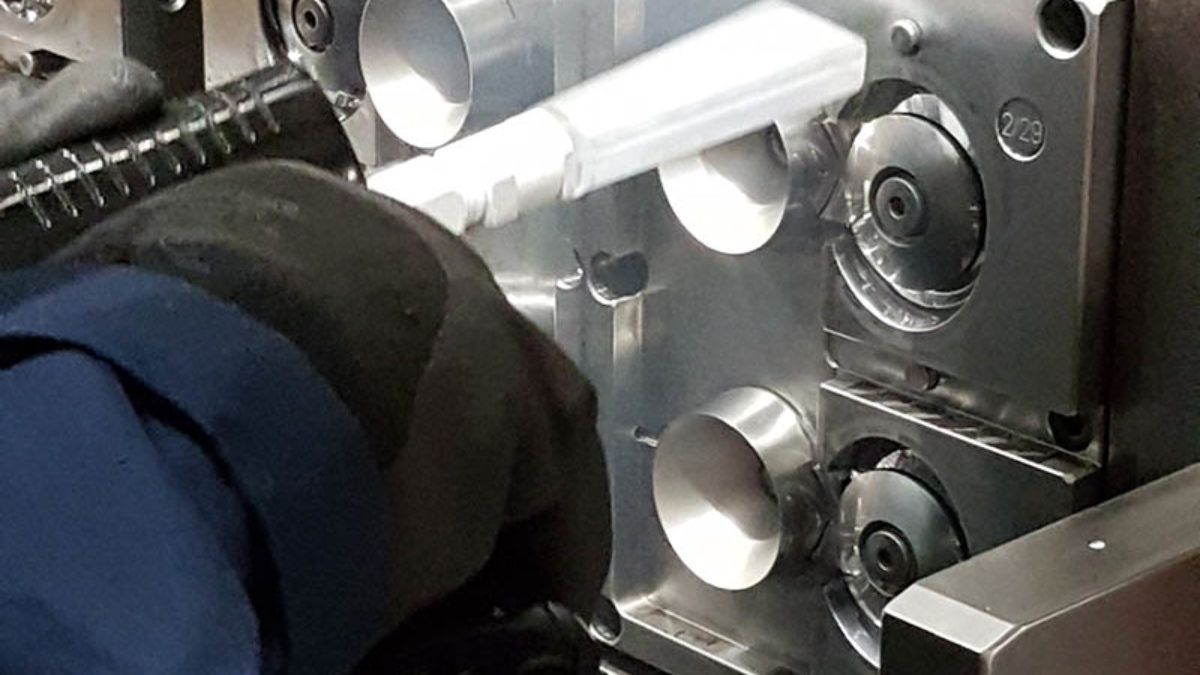

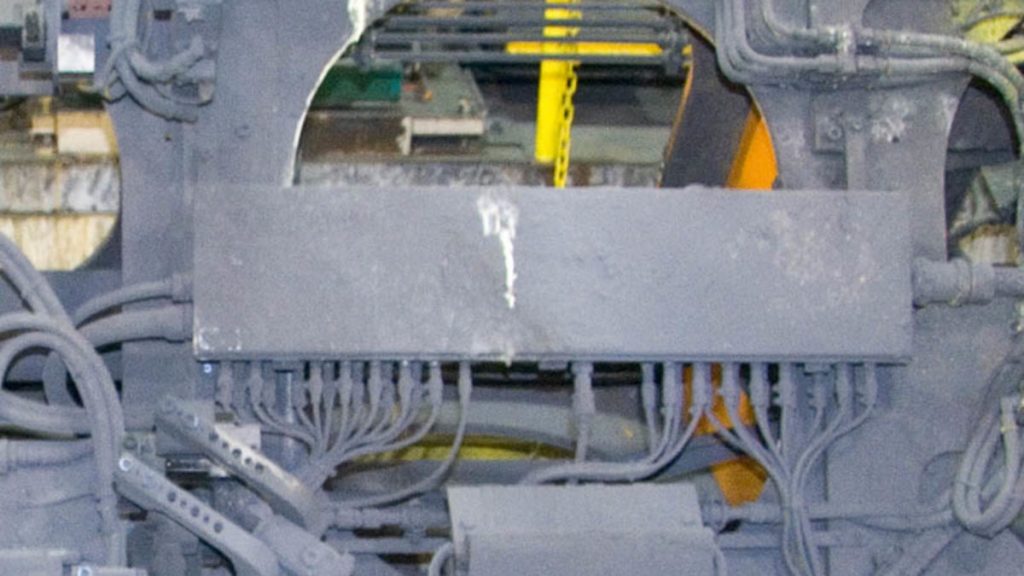

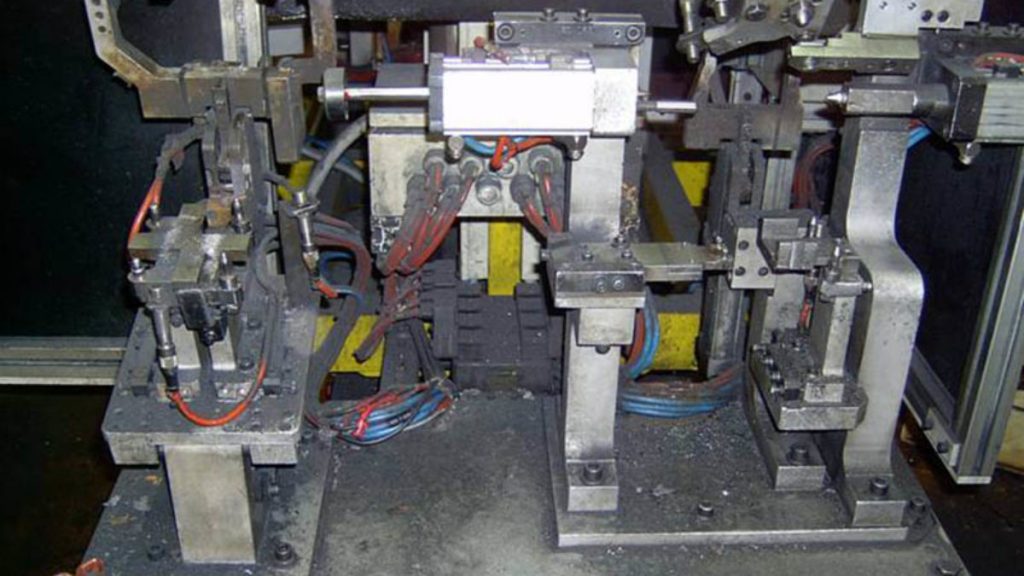

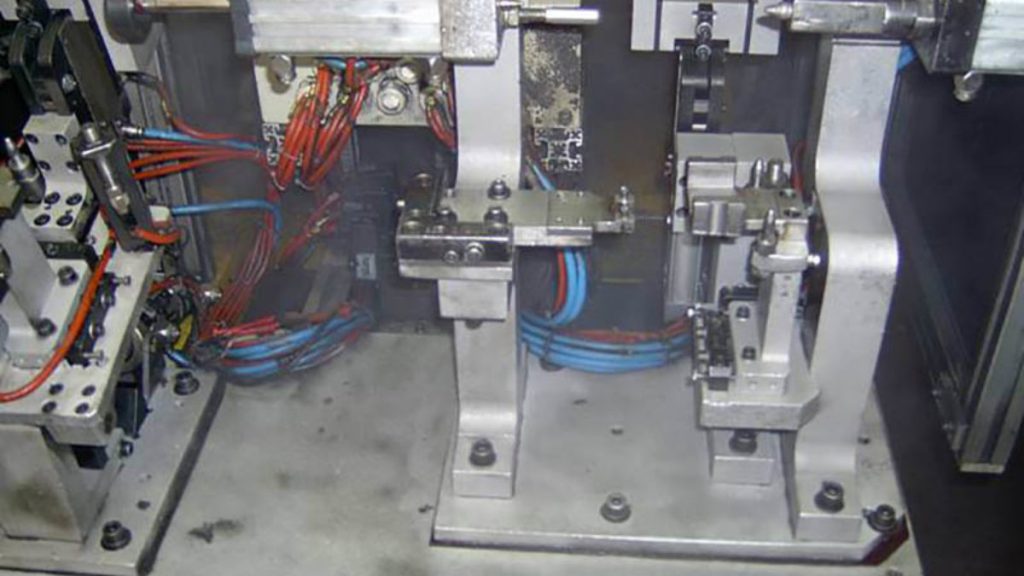

Weld Line Cleaning

Improve efficiency and accuracy of automated weld lines

BENEFITS

Dry ice cleaning eliminates misalignment, breakdowns and scrap by effectively removing weld slag and spatter buildup.

- Reduce scrap rates

- Maximize tooling life and decrease fixture repair

- Non-abrasive

Will not damage sensors - Replaces ineffective, costly and labor intensive cleaning methods

- Minimize downtime

- No secondary waste

- Environmentally responsible

- Clean online

No cool down required

SPECIFIC USE CASES:

- Robot joints

- Transfer cases

- Shuttle jigs

- Diamond plates

- Trunnions

- Weld tables

- Fixtures

- Proximity switches

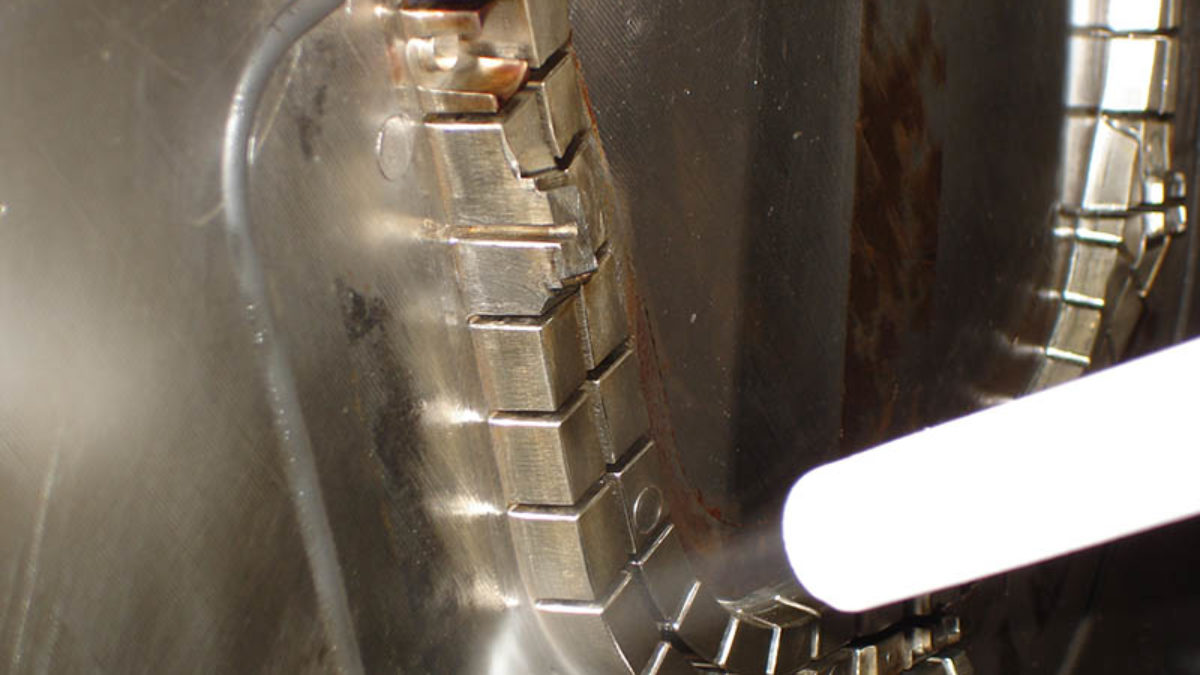

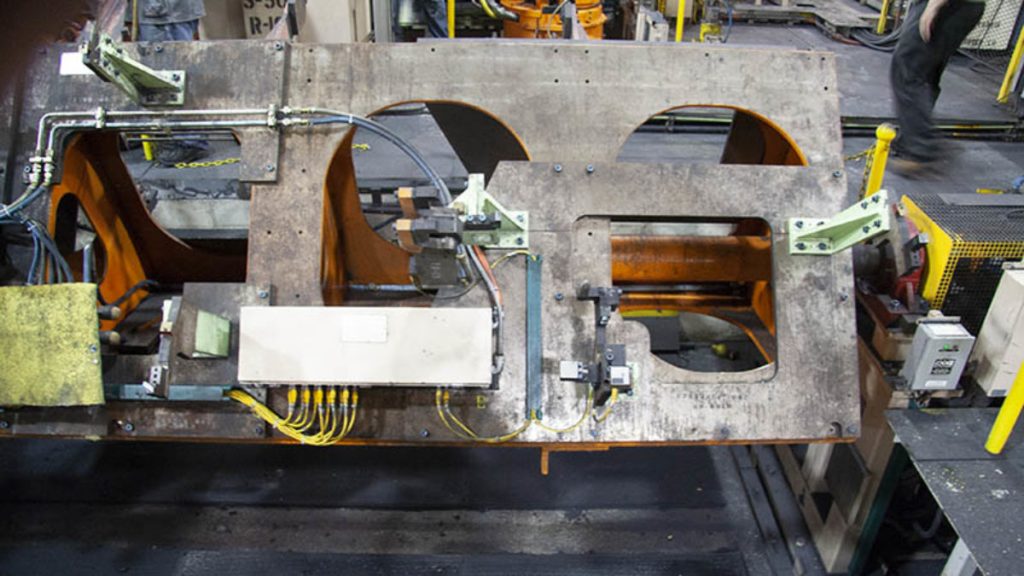

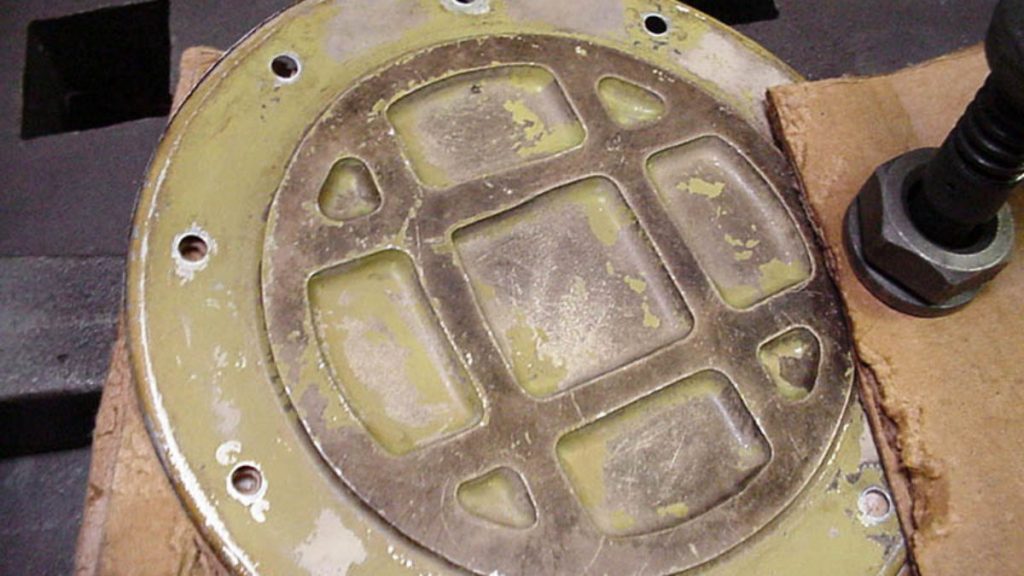

Foundry Cleaning

Significantly reduce cleaning time and resulting production downtime

BENEFITS

Dry ice blasting enables facilities to clean machinery and tooling in-place, at operating temperatures, without the risk of damage.

- Reduce production downtime

- Eliminate mold disassembly

Clean while hot and in-place - Clean more effectively

- Eliminate waste disposal cost

- Non-abrasive

No damage to tooling - Environmentally responsible

- Deliver superior as-cast finish

SPECIFIC USE CASES:

- Conveyors

- Core boxes and vents

- Die cast tooling

- Permanent aluminum molds

- Refractory coating

- Resins and release agents

- Semi-solid casting and forging tooling

- Shell core molds

- General part cleaning

- General equipment and facility cleaning

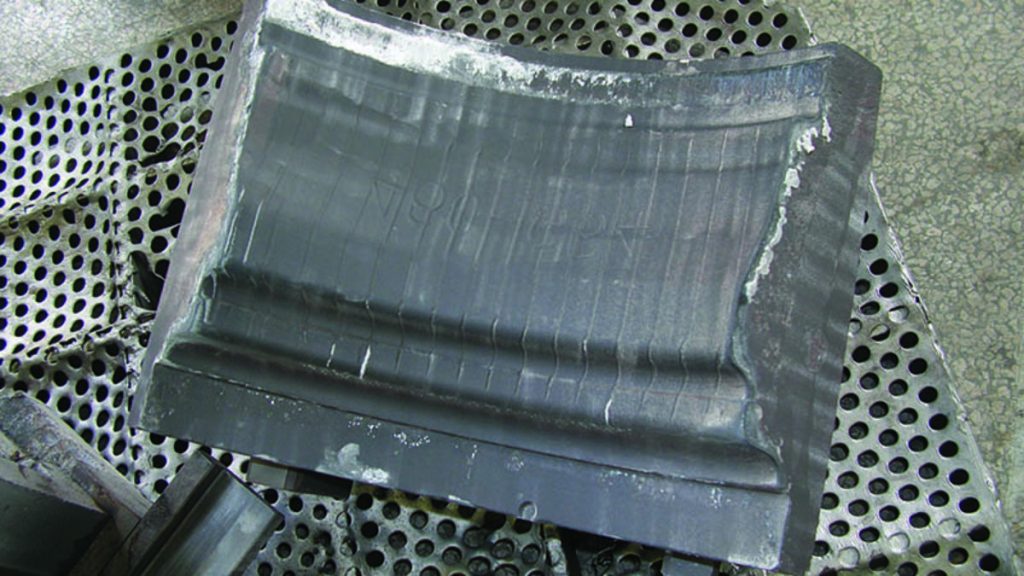

Parts Finishing Cleaning

Quickly and safely deburr and deflash parts

BENEFITS

Dry ice cleaning is a faster and more uniform flash and burr removal process that does not cause damage to the part.

- Faster and more uniform clean

- Elimination of cross contamination

- Non-abrasive

Lower scrap rates - Reduce cleaning costs and overall downtime

- Higher quality parts

- Eliminate manual cleaning

SPECIFIC USE CASES:

- PEEK

- PBT

- Acetal

- Nylon

- LCP

- ABS

- UHMWPE

- Nitinol

General Equipment Cleaning

Reduce cleaning time and production downtime while prolonging equipment life

BENEFITS

Dry ice blasting quickly and effectively cleans production equipment without water, chemicals or secondary waste.

- Reduce cleaning time

- Eliminate manual cleaning with harmful chemical solvents

- Non-conductive cleaning process

- No secondary waste

- Non-abrasive

Eliminate wear and tear on machinery - Reduce risk of unplanned production stoppages and costly repairs

- Environmentally responsible

- Clean in-place

No disassembly required - Enhance Total Productive Maintenance (TPM) programs

SPECIFIC USE CASES:

- Production equipment

- Ceilings and walls

- Equipment degreasing

- Electric motors and electric boxes

- Control panels

- Pipes, hoses and fittings

- Conveyors

- Cooling fans

- Hydraulic parts

- Robotics

- Sanding belts

- and more

BENEFITS OF DRY ICE BLASTING

Clean quicker and more effectively

while reducing production downtime

Significantly reduce cleaning time on a variety of applications within your automotive facility.

→ Decrease cleaning time and labor costs

→ Non-abrasive

No damage to product or equipment

→ Clean in-place

No disassembly required

→ Increase productivity and reduce downtime

→ Non-conductive cleaning process

→ Employee safe

Reduce harmful chemicals and tedious manual cleaning

→ Environmentally responsible

→ Improve part quality and reduce scrap

→ No secondary waste stream