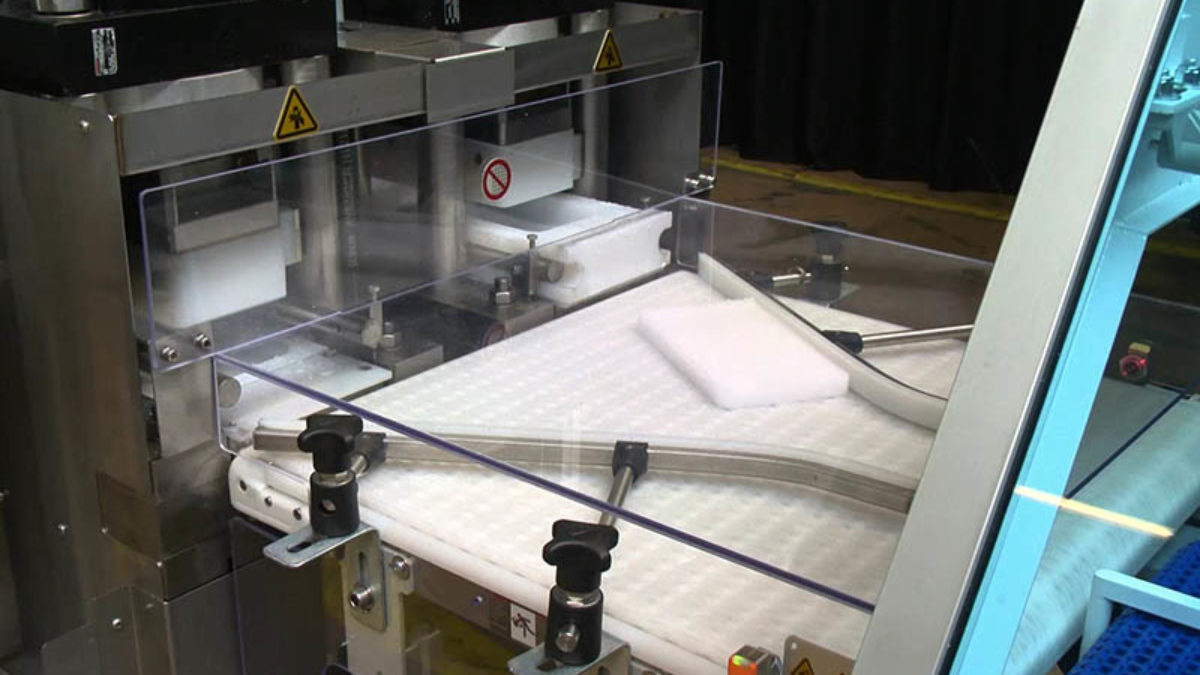

DRY ICE BLASTING APPLICATIONS:

Airline Catering

Onsite dry ice production is the ideal solution for onboard cooling in the airline catering industry

Airline caterers use large quantities of dry ice on a daily basis and dry ice represents a large percentage of non-food consumable costs. Complex scheduling often leads to dry ice waste and inefficiency.

By producing your own dry ice, airline caterers have complete control over dry ice availability, quality and cost.

BENEFITS OF DRY ICE PRODUCTION

Airline caterers experience decreased costs and greater flexibility with onsite dry ice production

Producing dry ice onsite leads airline caterers to reduce waste and decrease costs, while enabling them to meet unexpected changes to demand.

→ Greater flexibility to meet demand

→ Eliminate dry ice waste

→ Enhanced cooling

(3x the refrigeration power of water ice)

→ Cut costs and improve operational efficiency

→ Eliminate risk of over or under ordering

→ No residue or water

→ Eliminate delivery and storage costs

→ EPA, FDA and USDA approved for use around food

→ Fully automated, easy to use machines

→Cold Jet CONNECT™Remotely monitor, diagnose and implement corrective action