DRY ICE BLASTING APPLICATIONS:

Historical Restoration

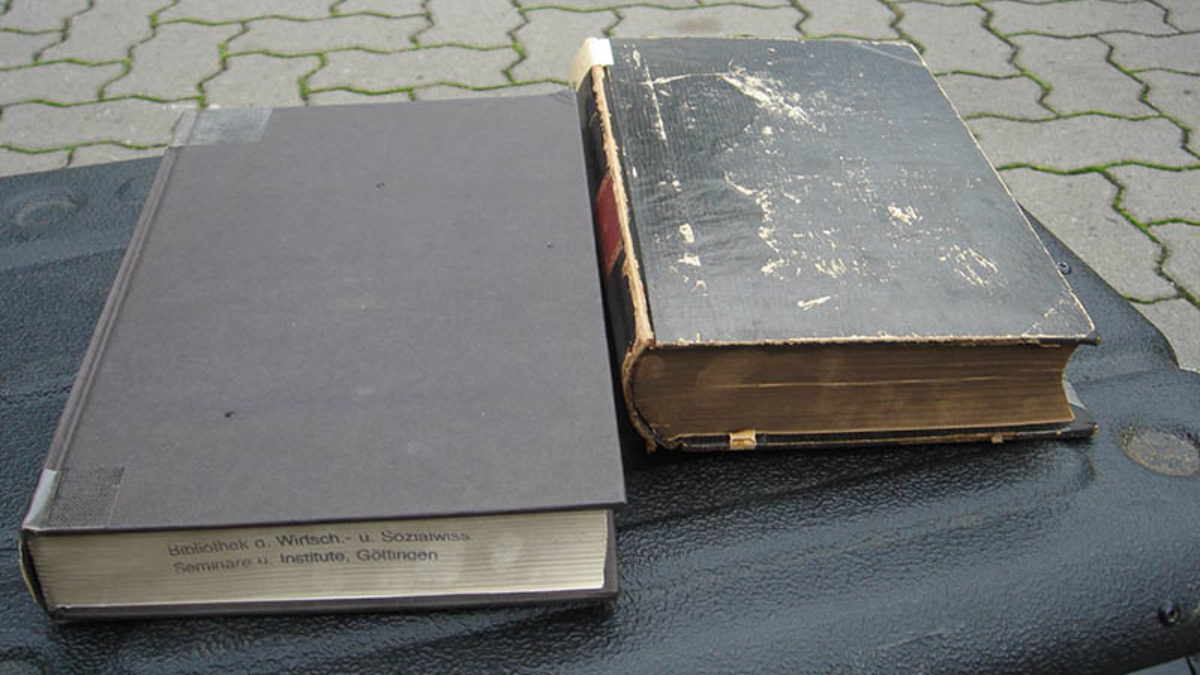

Safely restore historical items more quickly with non-abrasive cleaning method

Dry ice cleaning allows for safe and effective restoration of historical items in a fraction of the time of alternative methods. The process is non-abrasive and will not damage the delicate surfaces being cleaned. Dry ice blasting also eliminates manual cleaning with abrasive hand tools, harmful chemicals and water.

The dry ice blasting process is successful in removing layers of paint, carbon, pollution, smoke damage, mold and many other types of contaminants from all types of surfaces.

SPECIFIC USE CASES

Dry ice blasting safely removes all types of contaminants from historic artifacts and structures

RELATED INDUSTRIES

- Adhesive and tar removal

- Reversal of aging effect

- Fire and smoke damage

- Water damage

- Carbon buildup removal

- Failing paint removal

- Lead paint abatement

- Mold Remediation

- Removal of corrosive contaminants

BENEFITS OF DRY ICE BLASTING

Complete historical restoration projects safer, more quickly and at lower costs

Dry ice blasting eliminates abrasive hand tools and chemicals, while providing a faster restoration process that reduces labor, cleanup and disposal costs.

→ Non-abrasive

Will not damage sensitive or delicate surfaces

→ Chemical free process

Eliminate abrasive and harmful chemicals

→ Eliminate abrasive hand tools

→ Reduced restoration time

Remove contaminants faster and more effectively

→ No secondary waste

Reduce encapsulation and disposal costs

→ Environmentally responsible

Will not harm surrounding areas

→ Versatile clean

Clean a varying degree of surfaces