TEXTILES

Effectively and safely clean textile

production equipment online

Lint, glue and other buildup on production equipment is a common

problem within the textile industry. With dry ice blasting, buildup can be

removed quickly and without disassembly or damage to the equipment.

CASE STUDIES

Revolutionize processes

to drive real results.

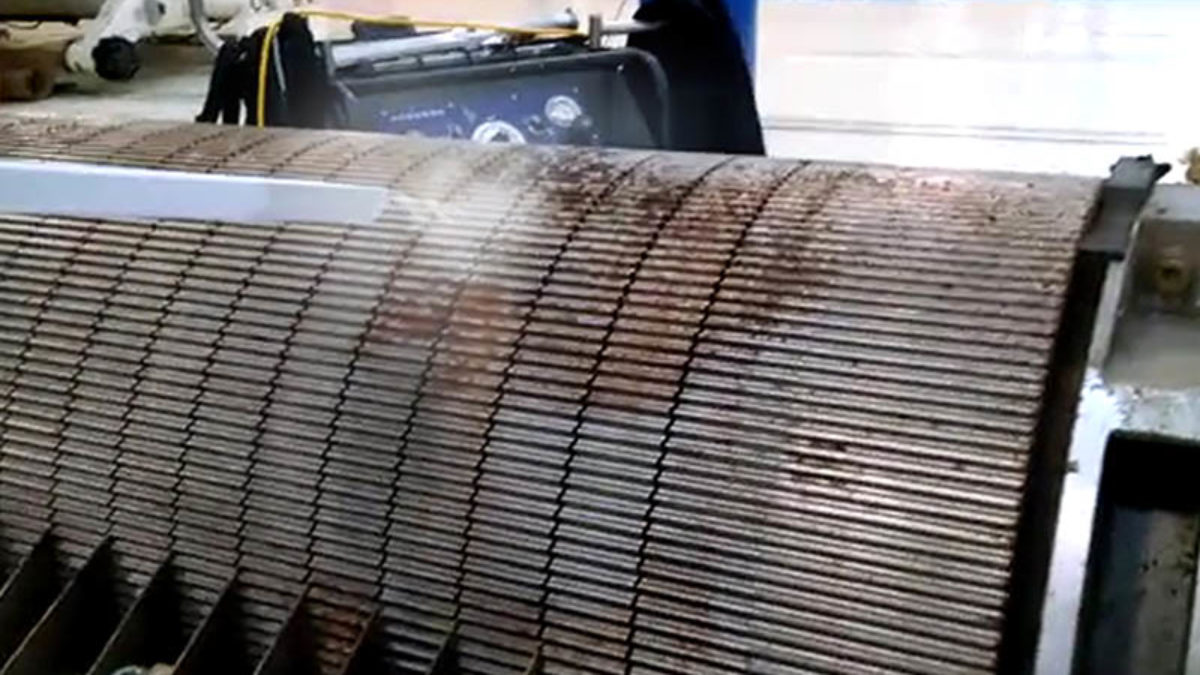

Textile Equipment Cleaning

Safely clean textile production equipment online

BENEFITS

Dry ice blasting safely removes buildup from production equipment for woven and non-woven textiles.

- Clean equipment while hot and online

- Reduce cleaning time and resulting downtime

- Improve preventative maintenance

- Clean in-place

No masking or de-energizing - No secondary waste streams or residue

- Environmentally responsible

- Non-abrasive

Will not damage equipment - Eliminate use of chemicals and solvents

SPECIFIC USE CASES:

- Tenter machines

- Tenter frames

- Converting machines

- Coating equipment

- Tenter chains

- Looming equipment

- Glue applicators

- Bag houses

- Pins and clips

- Conveyor systems

- Spools

BENEFITS OF DRY ICE BLASTING

Reduce production downtime while

increasing operational efficiency

Dry ice blasting cleans textile production equipment in-place, which enables facilities to increase production time and asset utilization rates.

→ Clean hot and online

Minimal to no disassembly required

→ Reduce cleaning time and resulting downtime

→ Improve preventative maintenance processes

→ Clean in-place

No masking or de-energizing

→ Environmentally responsible

→ No secondary waste streams

→ Non-abrasive

Will not damage equipment

→ Eliminate manual cleaning with harmful chemical solvents

→ Reduce risk of unplanned production stoppages and costly repairs